Monday, September 28, 2015

Snow & Ice: Three Ways to Cut Fleet Maintenance Costs written ...

Snow & Ice: Three Ways to Cut Fleet Maintenance Costs written ...: Three Ways to Cut Fleet Maintenance Costs written by John Ryynanen of Public Works Training. "Article in Fall Edition of "Cros...

Three Ways to Cut Fleet Maintenance Costs written by John Ryynanen of Public Works Training.

"Article in Fall Edition of "Crossroads" Quarterly publication of County Road Association of Michigan

John Ryynanen quoted from "Blue Collar Fleet Management" written by Mark A. Lester.

Excerpts below:

Tips from the experts:

The next maintenance step is thorough pre-trip and post-trip inspections ,and keeping up with preventative maintenance. Truck & Trailer Specialties ' Mark Lester advises fleet managers to supplement the manufacturers recommended preventive maintenance schedule with their own, based upon observations and experiences.

"With heavy maintenance trucks, your PM program cannot be static. You have to revisit it regularly and make adjustments based upon equipment breakdowns, problems, and other deficiencies that your operators and mechanics encounter during normal use and repair," he said.

During his 20-year tenure as fleet manager for MDOT's Southwest Region, :ester noticed through inspection and repair records the Class V trucks experienced battery failures after about three years in service.

To prevent batteries from failing or straining other charging system components, he adjusted the PM plan. Instead of waiting for battery failure, mechanics replaced the batteries before the three-year service life cycle.

"With heavy maintenance trucks, it is much better-and less expensive- the be proactive than reactive," he said.

One Chassis, many jobs (multi-functional trucks)

Mark Lester, product support specialist at Truck & Trailer Specialties, says multi-use trucks make the most sense when considering proactive versus reactive operational needs. "Plowing snow is reactive; spraying a bridge deck with brine to prevent ice from forming is proactive," Lester said. "Hook loaders provide the biggest bang for the buck because when you're not using them for high-priority reactive work, you can easily swap equipment and perform any number of other operations."

Further information on these topics and more can be obtained from my book "Blue Collar Fleet Management" available for purchase at: www.lulu.com.

Tuesday, July 14, 2015

Snow & Ice: Robins Book

Snow & Ice: Robins Book: All That Jazz By Mark Lester View this Author's Spotlight ...

Robins Book

All That Jazz

Paperback, 54 Pages

This item has not been rated yet

This item has not been rated yet

List Price: $25.00

Price: $21.25

You Save:$3.75( 15% )

Ships in 3-5 business days

A story of love and the struggles encountered in developing and maintaining a relationship and keeping love from being extinguished.

Thursday, May 28, 2015

Snow & Ice: https://www.youtube.com/watch?v=eTSUT854hqcCity ...

Snow & Ice: https://www.youtube.com/watch?v=eTSUT854hqc

City ...: https://www.youtube.com/watch?v=eTSUT854hqc City of Saginaw video of Swaploader equipped trucks. The use of hookloaders on governmental...

City ...: https://www.youtube.com/watch?v=eTSUT854hqc City of Saginaw video of Swaploader equipped trucks. The use of hookloaders on governmental...

https://www.youtube.com/watch?v=eTSUT854hqc

City of Saginaw video of Swaploader equipped trucks. The use of hookloaders on governmental agency trucks is rapidly gaining steam, and why shouldn't it? Great way to improve efficiency and truck usage, as explained in the video. Oakland County Road Commission just order 12 units (the same model as in the video). Time to "think outside the box".

Saturday, March 28, 2015

Snow & Ice: Presentations and speaking engagements

Snow & Ice: Presentations and speaking engagements: A little self promotion here; I have presented at several venues on the subject of fleet management practices and concepts. Some of ...

Presentations and speaking engagements

A little self promotion here; I have presented at several venues on the subject of fleet management practices and concepts.

Some of these presentations were through my employer, some "free gratis", and some as a paid speaker. I have never advertised; agencies and people have sought me out based upon recommendations of others and/or my book : Blue Collar Fleet Management" available from www.amazon.com or www.lulu.com. I do not offer any magic potent or secret formulas but rather simple concepts and practices I have used successfully as a fleet manager at Michigan Department of Transportation. My goal is to provide options and the advantages in implementing practices resulting in a paradigm shift among employees and in the end will increase efficiencies and reduce employee stress levels. As I transition into retirement mode I plan to increase my presentation business so one could view this post as my "coming out party"!

|

Presentation at APWA Fall Conference in Frankenmuth, MI where Robin and I presented |

|

West Virginia LTAP Conference Presentation 2014 |

Wednesday, March 4, 2015

Increased efficiency in snow removal operations with minimal capital outlay for equipment upgrade

Increased efficiency in removal of snow removal from trunkline. There are many ways to increase efficiency and raise productivity in winter maintenance operations. I am sharing one of these ways below. I have included an example which requires very minimal capital outlay for equipment upgrade. All it requires is upgrading to a 12 ft moldboard on a Patrol wing. This works very well on expressways and ramps.

|

| 9 ft Junior wing |

|

| 9 ft Junior wing in action |

|

| 12 ft Patrol Wing |

|

| 12 ft Patrol Wing in action |

|

| 12 ft Patrol wing in action |

Thursday, February 26, 2015

Snow & Ice: Is Winter Maintenance Truck Refurbishment a Sound ...

Snow & Ice: Is Winter Maintenance Truck Refurbishment a Sound ...: Refurbishment of winter maintenance trucks as opposed to replacement with new models has become a “hot topic” the last few years. I think...

Is Winter Maintenance Truck Refurbishment a Sound Fleet Management Practice?

Refurbishment of winter maintenance trucks as opposed to replacement

with new models has become a “hot topic” the last few years. I think initially, at least, there was a fear

by fleet managers, and deservedly so, of the impact of the newer emission

standards and engine designs on engine costs and reliability. Refurbishing existing trucks allowed fleets

to avoid the newer engine designs and potential problems, which is completely understandable. However, with the implementation of “downstream”

exhaust treatment to meet the more stringent emission standards reducing need

for increased exhaust gas recirculation and other adjustments, engine performance

and reliability has returned to the engines of the “good old days”. Avoiding

the newer engine designs due to fear of unreliability is no longer a

justifiable decision.

I have been “accused” of having a negative opinion of winter

maintenance truck refurbishment as an option when trucks are due for replacement

and that is generally a fair accusation.

I think the term “refurbishment” used by fleet managers and vendors does

not have a common definition. What I

notice is generally the trucks being refurbished have been allowed to

deteriorate to almost a junk status. In

these instances, refurbishment becomes restoration. In this type of scenario then

I am definitely in opposition. Agencies that are engaged in this type of

activity generally lack any proactive preventative maintenance program which in

my opinion is a very poor business practice and misuse of public funds. I

prefer not to allow trucks to deteriorate to an unusable condition by adhering and

practicing a sound preventative and predictive maintenance program throughout

the life of the truck.

This practice results in a couple of things: a.) spreads out the maintenance costs over the

life cycle of the truck eliminating a major expenditure in a solitary budget

year, b.) reduces out of service time or at least spreads it out over the life

cycle of the truck, and c.) extends the service life of the major components,

i.e. engine & drive train. If a refurbishment

is forecast in the future of a well maintained winter maintenance truck the end

result will be less work required resulting in less cash outlay and out of

service time to bring the truck back to O.E.M. standards. Or you have the option of selling the truck

while it still has useable service life remaining and investing the proceeds of

the sale in a new truck with the newest technology, driver comfort, and safety

features. If you follow this practice

over time you will gain the reputation as a well maintained fleet and the

trucks you sell will be in higher demand which will increase revenue from used

truck sales. In my opinion, this is a far better approach.

I may be harsh, but I believe the agencies engaged in the

total restoration (refurbishment by their definition) of older trucks are

guilty of poor fleet management including preventative maintenance which they

attempt to solve by having someone else perform all the tasks that these agencies

neglected during the life of the truck.

A significant danger to refurbishment and reuse of older trucks

is parts availability due to discontinuance of truck makes and models. A good example: while at MDOT we recycled two Ford L-8000

truck chassis from winter maintenance to herbicide application units. Winter maintenance is a severe duty application

while roadside herbicide application is light duty and can greatly extend the

usable life of a truck chassis. This

worked well for us; these trucks were well maintained, they were dependable, and

we saved the cost of a new truck chassis for a limited use seasonal type operation

(although these were anti-ice/vegetation combination units). However, once Ford Motor Company halted production

of heavy duty trucks some of the replacement parts became scarce and very expensive.

Cab body parts were one example but the best example I can provide

is the dipstick tube for the Allison automatic transmission. These dipstick tubes were specific to the

truck make & model and so the demand for them dropped to almost zero. We broke a dipstick tube while removing transmission

pan and when we went to purchase a replacement we discovered: a. they were almost as scarce as dinosaur

teeth and b.) when we did locate one our

cost was $1,000.00 and the delivery time was close to a month. This is not a good situation to find yourself

in and even worse if it is a winter maintenance truck during the winter season.

My advice to you; do

your homework and think this through. To learn more about sound proven fleet management practices I suggest you purchase my book: "Blue Collar Fleet Management" available from the publisher www.lulu.com.

Tuesday, February 24, 2015

Snow & Ice: Chuck Clark and Jim PagelsThese two guys were the...

Snow & Ice: Chuck Clark and Jim Pagels

These two guys were the...: Chuck Clark and Jim Pagels These two guys were the very first field mechanics out of the MDOT Southwest Region Central Repair Facility...

These two guys were the...: Chuck Clark and Jim Pagels These two guys were the very first field mechanics out of the MDOT Southwest Region Central Repair Facility...

Tuesday, February 10, 2015

Snow & Ice: Restored Michigan Department of Transportation 194...

Snow & Ice: Restored Michigan Department of Transportation 194...: Indian in the Snow by Pat Miller; MDOT retired The story of the sno-go, 040904, began in 1947 when the United States Government...

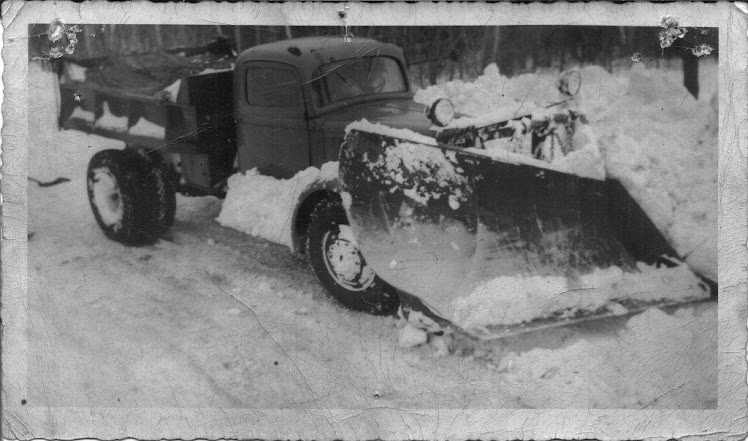

Restored Michigan Department of Transportation 1947 Osh Kosh Sno Go in action

Indian in the Snow

by Pat Miller; MDOT retired

The

story of the sno-go, 040904, began in 1947 when the United States Government

established a contract with the Oshkosh Motor Truck Company. The contract

(N160-2605) was made to provide twenty-eight heavy duty four wheel drive trucks

with rotary sno-blower attachments to help aide in snow removal and daily

maintenance of the roads. The Sno-go was assigned to the Army Corp of Engineers

at the time to help aide in daily maintenance of the Alcan Highway in Alaska Washington Kalkaska , Michigan

The

sno-go now had a new roads and a new home in Kalkaska, it was now blowing the

Northern part of District three, and these roads were from Elmira Hill on US131

between Antrim and Charlevoix

County Michigan Lansing , Brighton and Niles ,

Michigan

The

storm of 1978, the sno-go was gone for approximately five weeks, running

twenty-four hours a day clearing and widening roads in the Southern part of the

state. When the sno-go returned the 8’ cutter bar on the right side of the

blower had the paint worn off right down to the metal indicating it had been

working in snow drifts that exceeded eight feet tall. During that same storm

while out blowing East of Honor, Michigan

The

winter of 1981 & 1982 was unusually brutal and the years of use began to

show, so in the fall of 1982 the sno-go saw its next update. As the mechanic,

Louie Hunt who was under the direction of Jerry Hodge, were preparing for

winter, updates to the sno-go were performed, the rear engine was beginning to

weaken and parts for the old Climax gas engine were becoming scarce and the

amount of fuel it used was tremendous (100 gallons in 8 hours) so it was then

decided to replace the old gas engine with a rebuilt diesel engine, this

changeover was done in record time due to the winter season approaching.

After

more than ten years of less than average snow fall, the sno-go rested

comfortably in the MDOT storage barn in Kalkaska. In the spring of 2006, the

sno-go was then called upon to perform a special project as a part of the

celebration of MDOTs 100th birthday. The sno-go was needed to escort

the department director, Gloria Jeffs, in the National Cherry Festival’s,

Heritage Parade which occurs the first weekend of July in Traverse City, the

only problem was it looked as though it

had been setting for more than ten years. That May, Pat Miller began to restore

the sno-go back to its original condition on his own time making sure it was

spotless for its stroll in the parade. The sno-go was in need of a major

facelift, painting began to restore the highway orange color, new stickers and

graphics were placed on the freshly painted body and the engine was tuned up so

it was running just like new. Since then it has been seen in many local events

around the area, Pat Miller even received the directors award for his hard work

restoring the sno-go.

The

future of this grand old Indian is much in doubt, if sold at an auction it will

no doubt be dismantled, having the rear engine removed to power a generator set

or pump water. The axle and transfer case could be used to build a swamp buggy

and/or monster truck. Not a very fitting end to a long and luxurious career

that has saved a person’s life, kept roads clear and safe for drivers and has

become such an icon for MDOT. This truck has played a major role in the

transportation history of Michigan Michigan

Friday, February 6, 2015

Snow & Ice: TowPlow is Uni Mog?

Snow & Ice: TowPlow is Uni Mog?: The TowPlow Tow Plow will be the Uni Mog Uni Mog with ice cutter ...

Friday, January 30, 2015

My newest book is now in print. It is a little higher priced than I would have wished but it has loads of color pictures and color ink is expensive.

http://www.lulu.com/shop/mark-lester/they-call-me-davy-crocket-san/paperback/product-22020415.html

http://www.lulu.com/shop/mark-lester/they-call-me-davy-crocket-san/paperback/product-22020415.html

| Geeky picture but hey; you cannot lie to a camera |

Thursday, January 29, 2015

http://www.wwmt.com/news/features/top-stories/stories/Kalamazoo-Co-Road-Commission-pre-treating-in-advance-of-anticipated-ice-71983.shtml#.VMofBGd0zIU

We built this tanker at Truck & trailer Specialties. It has been a challenge as the tanker does chloride applications for dust control in the summer at a rate of 1,500 to 2,000 gallons a lane mile and then does anti-ice application in the winter at a rate of 20 - 30 gallons a lane mile. Obviously, this is a huge difference in application rates.

We built this tanker at Truck & trailer Specialties. It has been a challenge as the tanker does chloride applications for dust control in the summer at a rate of 1,500 to 2,000 gallons a lane mile and then does anti-ice application in the winter at a rate of 20 - 30 gallons a lane mile. Obviously, this is a huge difference in application rates.

|

| Great Lakes Chloride Tanker |

Subscribe to:

Posts (Atom)